Varistor acts like a guardian for electronic circuits, stepping in when voltage spikes threaten sensitive components. Its resistance doesn’t stay the same—instead, it changes dramatically as the voltage rises, which helps absorb sudden surges. Many devices use metal oxide varistors (MOVs) because they handle a wide range of voltages and respond in less than one nanosecond. The numbers below show just how adaptable these components are:

| Specification | Details |

|---|---|

| Varistor Chip Diameter | 5 mm |

| Pressure Sensitive Voltage | 18 to 750 V |

| Maximum Allowable Voltage | 11 to 460 V (AC), 14 to 615 V (DC) |

| Flow Capacity @1KHz | 30 to 1400 pF |

| Nonlinear Coefficient | 20 to 40 |

| Energy Absorption Capacity | Up to 10 kJ |

| Response Time | Less than 1 nanosecond |

| Leakage Current | Minimal |

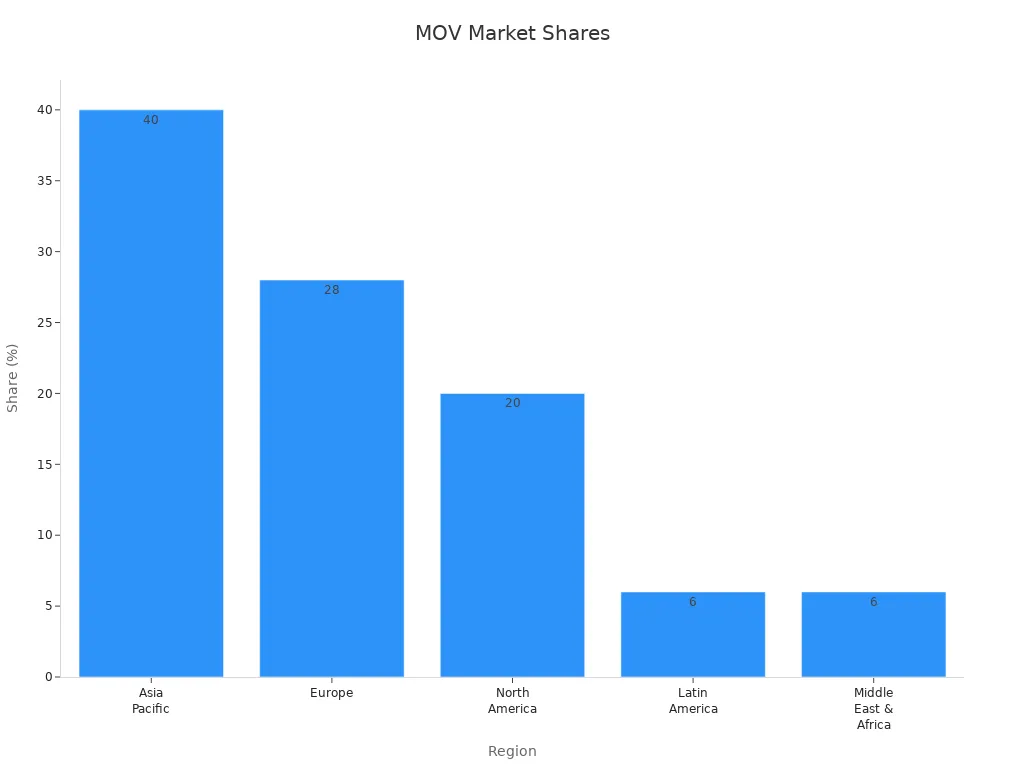

Today, MOVs dominate the global market, with Asia Pacific leading at about 40% of all sales. Their popularity keeps climbing, as shown in the chart below.

Key Takeaways

- Varistors protect electronic circuits by quickly absorbing dangerous voltage spikes to prevent damage.

- Metal oxide varistors (MOVs) are popular because they respond in less than a nanosecond and handle a wide voltage range.

- A varistor changes its resistance based on voltage, acting like a smart gatekeeper that opens only during surges.

- Choosing the right varistor involves matching voltage and energy ratings to your system and planning for regular checks and replacements.

- Regular testing and inspection help spot varistor failures early, keeping your electronics safe and extending their life.

Varistor Basics

Definition

A varistor is a special type of resistor that changes its resistance depending on the voltage applied across it. When the voltage stays within normal limits, the varistor acts like an insulator, letting very little current pass through. If the voltage suddenly jumps above a certain level, the varistor’s resistance drops sharply, allowing it to absorb and redirect the extra energy. This unique behavior makes it a go-to component for protecting electronic circuits from voltage spikes and surges. Industry standards describe the varistor as a voltage-dependent resistor (VDR) with a non-linear volt-ampere characteristic, designed to clamp voltage and shield circuits from overvoltage. The most common type, the metal oxide varistor (MOV), uses zinc oxide as its main material and offers fast, reliable voltage clamping.

Tip: Think of a varistor as a smart gatekeeper—it stays closed during normal operation but opens instantly to block dangerous voltage surges.

Structure

The inside of a varistor looks simple, but its design is quite clever. Most MOVs have a ceramic block made from tiny zinc oxide grains mixed with other metal oxides. These grains form a network, and the boundaries between them act like tiny diodes. Under normal voltage, these boundaries block current, but when the voltage gets too high, they break down and let current flow. The main parts of a varistor include:

- A ceramic body made of zinc oxide and other metal oxides

- Metal electrodes attached to both sides

- Protective packaging to keep out moisture and dust

Scientists use tools like X-ray diffraction and scanning electron microscopes to study the microstructure. They find that the size of the grains, the way they connect, and the presence of special bismuth-rich phases all affect how well the varistor works. For example, microwave-sintered varistors often have more uniform grains, which can improve performance.

| Component | Function |

|---|---|

| ZnO Ceramic Body | Main surge-absorbing material |

| Metal Electrodes | Provide electrical connection |

| Grain Boundaries | Act as semiconductor junctions for protection |

| Packaging | Shields from environment |

Circuit Protection

Varistors play a key role in keeping electronic devices safe. When a sudden voltage spike—like a lightning strike or a power surge—hits a circuit, the varistor reacts almost instantly. Its resistance drops, and it channels the excess energy away from sensitive parts. This action is called voltage clamping. Engineers test varistors by applying short bursts of current and measuring how well they clamp voltage. For example, a typical test uses a current of 0.5mA to 1mA for just a few seconds to check if the varistor still works without causing damage. The clamping voltage, or the highest voltage the varistor can handle before it conducts, is a key measurement. If the varistor passes this test, it means the device can still protect the circuit from future surges.

Note: Varistors respond in nanoseconds, making them much faster than many other surge protection devices. This speed is crucial for protecting delicate electronics.

Working Principle

Voltage-Dependent Resistance

A key feature of these protective devices is their ability to change resistance based on the voltage applied. When the voltage remains low, the device acts almost like an insulator, letting only a tiny current pass. As the voltage increases, the resistance drops sharply, allowing more current to flow. Scientists have used computer models and real-world tests to study this effect. For example, researchers modeled zinc oxide ceramics and found that the current flows unevenly through the material, depending on the voltage. The boundaries between the tiny grains inside the device act like switches, turning on when the voltage gets high enough. Studies on tin oxide-based ceramics show that this non-linear behavior holds true across a wide range of currents. The nonlinearity coefficient, which measures how much the resistance changes, can reach values around 50 in the most active region. This means the device responds quickly and strongly to voltage changes, making it ideal for protecting electronics.

Surge Protection

These devices shine when it comes to stopping dangerous voltage surges. They absorb and redirect extra energy, keeping sensitive equipment safe. Engineers look at several key numbers to judge how well a surge protector works. The joule rating tells how much energy the device can handle. Basic models can absorb 140 to 410 joules, while whole-house protectors can handle over 3,000 joules. The clamping voltage is another important number—it must stay below the level that could harm connected equipment. Fast response time is also crucial. Industry standards require high-end models to react in less than one second, but most react much faster. Studies show that surge protectors meeting strict standards can cut surge damage by over 90% and help electronics last more than 30% longer.

| Parameter | Description | Typical Value/Result |

|---|---|---|

| Joule Rating | Energy absorption capacity | 140–410 J (basic), 3000+ J (whole-house) |

| Clamping Voltage | Max voltage allowed to protect equipment | Below equipment withstand voltage |

| Response Time | Speed of activation | ≤1 second (industry standard), often faster |

| Effectiveness | Surge damage reduction, equipment life boost | >90% damage reduction, >30% life extension |

Response Time

Speed matters when stopping a surge. These devices react in nanoseconds to microseconds, depending on their design and materials. For example, some models respond in about 25 nanoseconds, while others can act in as little as 1 nanosecond. The response time depends on factors like the size of the device, the type of material used, and the way it is built. Fast response means the device can clamp down on a surge before it reaches sensitive parts of a circuit. The table below shows how different models compare:

| Model | Response Time | Clamping Voltage | Peak Current | Notes |

|---|---|---|---|---|

| General ZnO Devices | ns–μs | Varies | Varies | Depends on load and geometry |

| Littelfuse V10E275P | μs range | Up to 350 V | Up to 3.5 kA | Stable specs, low temp sensitivity |

| EPCOS B72220S151K101 | ~25 ns | 395 V | 8 kA | Fast, for AC line protection |

| Eaton MLVB06V18C003 | ~1 ns | 18 V | N/A | Very low capacitance, ideal for small devices |

⚡ Quick response times help prevent damage from even the fastest voltage spikes, making these devices a reliable choice for modern electronics.

Parameters and Functions

Key Parameters

Engineers look at several important numbers when they choose a device for circuit protection. These numbers help them understand how well the device will work in real situations. Some of the most important parameters include nominal voltage, voltage ratio, peak transient current, residual voltage ratio, and current capacity. Each one tells a different story about how the device will react to a surge or spike.

- Nominal Voltage: The regular voltage the device can handle without turning on.

- Peak Transient Current: The highest surge current it can safely absorb.

- Residual Voltage: The voltage that remains after the device clamps a surge.

- Nonlinear Coefficient (α): Shows how sharply the resistance drops as voltage rises.

Laboratory tests help confirm these ratings. Engineers measure resistance at different voltages and plot curves to see how the device behaves. They also run voltage ramp tests to find the exact point where it starts to conduct. These tests make sure the device will protect circuits at the right time and can handle strong surges. Studies show that the way grains and impurities are arranged inside the device can change these parameters a lot. For example, adding certain oxides or making the grains more uniform can boost performance and prevent breakdowns.

Main Functions

These devices do more than just block surges. They act as fast switches, turning on only when needed. In high-energy systems, such as those found in scientific labs or power plants, they help discharge coils quickly and keep temperatures low during faults. Engineers have tested them in special units for superconducting coils, where they proved to shorten discharge times and protect against overheating. Computer models and real-world experiments both show that these devices can handle tough jobs, like absorbing lots of energy and surviving rapid heating. They also help combine different protection tasks into one unit, making systems simpler and more reliable.

💡 These devices not only protect electronics but also improve safety and reduce repair costs in demanding environments.

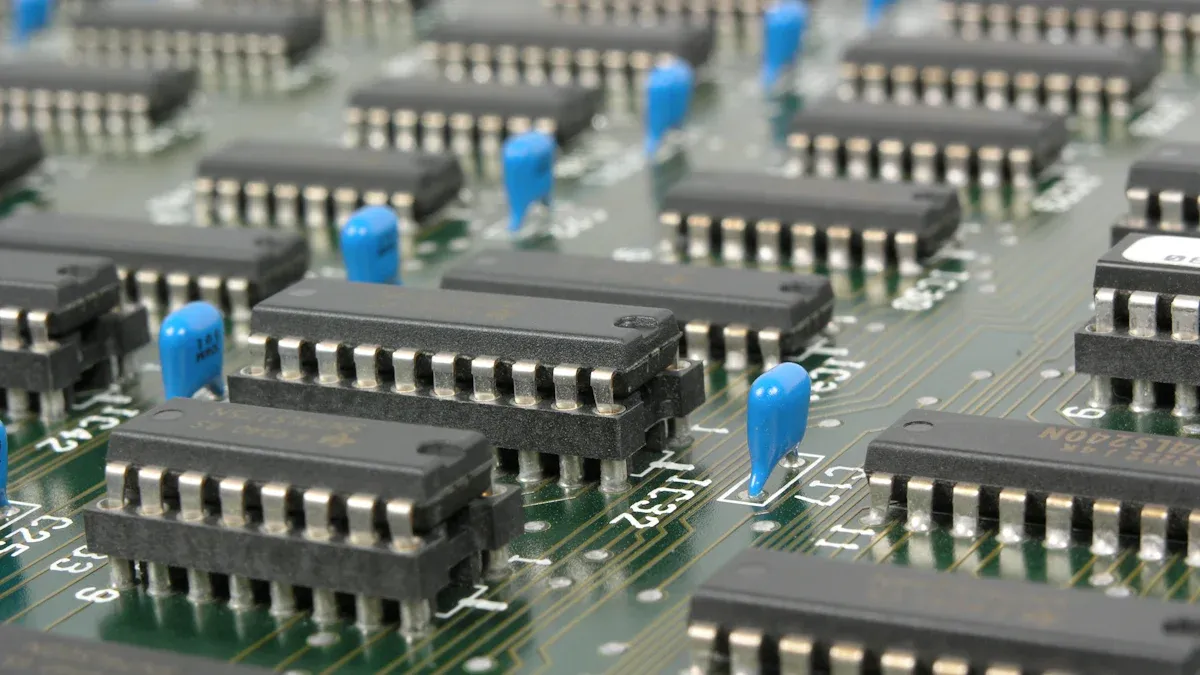

Applications

People use these protective devices in many places. They show up in homes, factories, cars, and even renewable energy systems. Here are some real-world examples:

- In factories, special models cut equipment downtime by 40% by stopping voltage surges from machines.

- Phone networks use them to guard against lightning, keeping calls and data flowing.

- Home appliances like fridges and air conditioners last longer and need fewer repairs thanks to these devices.

The market for these devices keeps growing, especially with more electric cars and smart gadgets. They protect sensitive parts in electric vehicles, smart grids, and even solar panels. The table below shows where they are most common:

| Application Sector | Description |

|---|---|

| Consumer Electronics | Used for surge protection in everyday devices. |

| Telecommunications | Shields communication gear from spikes and lightning. |

| Home Appliances | Prevents damage in household devices. |

| Automotive | Guards vehicle electronics from sudden voltage changes. |

| Industrial Equipment | Protects machines and control systems from power swings. |

| Renewable Energy Systems | Keeps solar and wind equipment safe from voltage problems. |

Metal Oxide Varistor

MOV Structure

A Metal Oxide Varistor, or MOV, has a unique structure that sets it apart from other surge protection devices. Inside, tiny grains of zinc oxide mix with other metal oxides. These grains form a network with many boundaries, which act like back-to-back diodes. This special setup gives the MOV its ability to change resistance quickly when voltage spikes. Scientists use advanced tools like Electron Energy Loss Spectroscopy and Scanning Electron Microscopy to study these materials. These tools help them see the grains, measure pore sizes, and check how the elements spread out. By understanding the structure at such a small scale, engineers can design MOVs that work better and last longer.

MOV Advantages

MOVs stand out because of their reliable performance and strong surge protection. The zinc oxide grains create a nonlinear current-voltage relationship. At normal voltages, the MOV blocks current, but when a surge hits, it lets current flow and absorbs the extra energy. This behavior is symmetrical, so it works the same way for both directions of current. Studies show that MOVs have higher nonlinear coefficients and lower leakage currents than other types of varistors. Some of the latest MOVs reach nonlinear coefficients up to 219 and can handle high electric fields. These features make MOVs the top choice for protecting sensitive electronics from sudden voltage changes.

🛡️ MOVs offer both high performance and reliability, making them a favorite for engineers who need strong surge protection.

MOV Selection

Choosing the right MOV for a circuit takes careful planning. Here are some important steps:

- Check the voltage rating to match the system’s normal voltage.

- Make sure the MOV can absorb the expected surge energy.

- Pick a clamping voltage that protects equipment without being too restrictive.

- Confirm the MOV fits the available space and mounting style.

- Combine voltage and energy ratings for proper sizing.

- Place MOVs at key points in the circuit for best protection.

- Consider the environment, such as temperature and humidity.

- Plan for regular inspection and replacement, since MOVs wear out over time.

A well-chosen MOV keeps electronics safe and helps them last longer.

Varistor Failure and Testing

Failure Signs

Varistors can fail in several ways, and knowing what to look for helps keep circuits safe. Common failure signs include:

- Electrical puncture, which happens when a small varistor faces a long-lasting current. This can melt parts inside and break the conduction path.

- Physical cracking, often seen after a big, short surge. Cracks usually appear at the edges where grain sizes vary.

- Thermal runaway, which occurs if the device gets too hot from steady current. The temperature rises quickly and can cause the varistor to break down.

- Multipulse lightning surges, where several strikes hit within milliseconds. This causes heat to build up and can lead to failure, even if a single surge would not.

Field studies show that most failures happen during real-world surge events, not just in lab tests. For example, researchers found that five strong surges spaced closely together could destroy a varistor, while many spaced-out surges did not. Visual signs of failure include cracks, discoloration, swelling, or burn marks.

🔍 Regular inspection for these signs helps prevent bigger problems in your electronics.

Varistor Testing

Testing a varistor ensures it still works as a protector. Here are some common tests and what they show:

| Test Type | Purpose/Outcome Description |

|---|---|

| Varistor Voltage Test | Checks the voltage where the device starts to conduct. |

| Clamping Voltage Test | Confirms the highest voltage allowed during a surge. |

| Leakage Current Test | Measures current under normal voltage; high values mean degradation. |

| Surge Current Test | Tests if the device can handle strong surges. |

| Insulation Resistance Test | Makes sure no current leaks to other parts of the circuit. |

To test with a multimeter:

- Turn off and discharge the circuit.

- Set the meter to resistance mode.

- Touch the probes to the varistor leads.

- A good varistor shows high resistance (in megaohms). Low resistance or a short means failure.

- Switch probe direction and check for similar readings.

If you see low resistance, inconsistent readings, or physical damage, replace the device.

Selection Guidelines

Choosing the right varistor means matching it to your system’s needs. Use these tips:

- Check the voltage rating. It should be higher than the normal working voltage but lower than the level that could harm your equipment.

- Look at the current rating. Make sure it can handle the biggest surge your system might face.

- Review charts for transformer or circuit ratings to match voltage and current.

- Consider the environment. High temperatures, moisture, or chemicals can shorten lifespan.

- Pick a size and shape that fits your space and mounting needs.

- Plan for regular checks and replacement, especially after big surges.

🛠️ The right choice keeps your electronics safe and working longer.

Varistors keep electronics safe by stopping voltage surges before they cause harm. Today’s devices offer better energy absorption and faster response, thanks to new materials and smarter designs. The market keeps growing as more people use smart devices, renewable energy, and advanced cars. Engineers who know how to pick and test these protectors help equipment last longer and meet strict safety rules.

As technology moves forward, improved surge protection supports the future of electronics everywhere.

FAQ

What happens if a varistor fails?

A failed varistor often shows cracks, burns, or swelling. The device may stop protecting the circuit. Sometimes, it can short out and cause the fuse to blow. Regular checks help spot these problems early.

Can you reuse a varistor after a surge?

No, engineers recommend replacing a varistor after it absorbs a strong surge. The device may look fine, but its protection level drops. Using a damaged varistor puts electronics at risk.

How do you know which varistor to choose?

Check the system’s normal voltage and the highest surge it might face. Pick a varistor with a voltage rating just above normal and a current rating that matches the worst-case surge. Always follow the manufacturer’s charts.

Are varistors safe for all electronics?

Most electronics use varistors safely. Sensitive devices, like medical equipment, may need extra care. Always check the datasheet and use the right size for the job.

Do varistors wear out over time?

Yes, varistors age with each surge they absorb. Heat, moisture, and repeated spikes speed up wear. Plan to inspect and replace them during regular maintenance.